Products Details

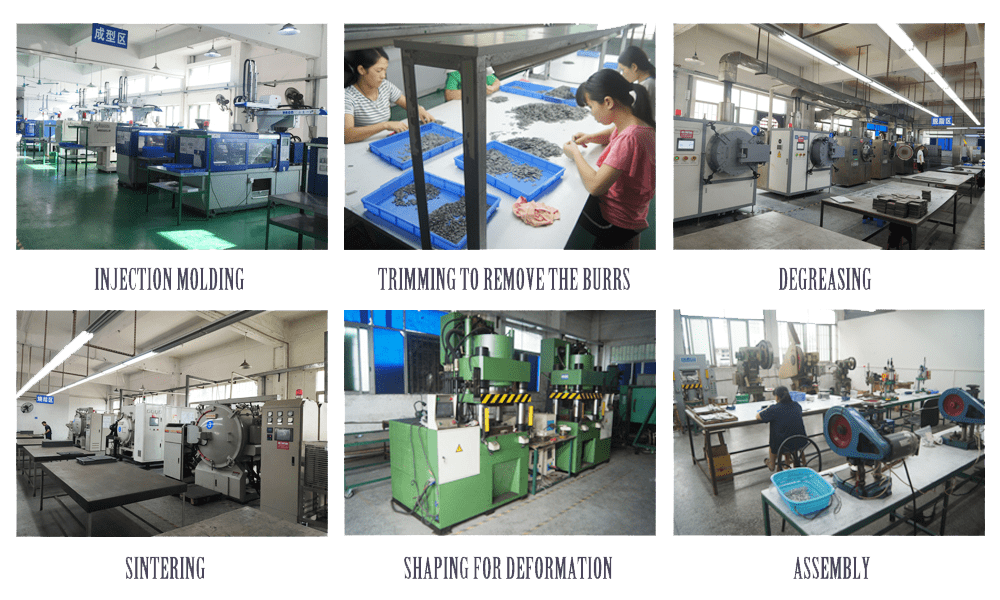

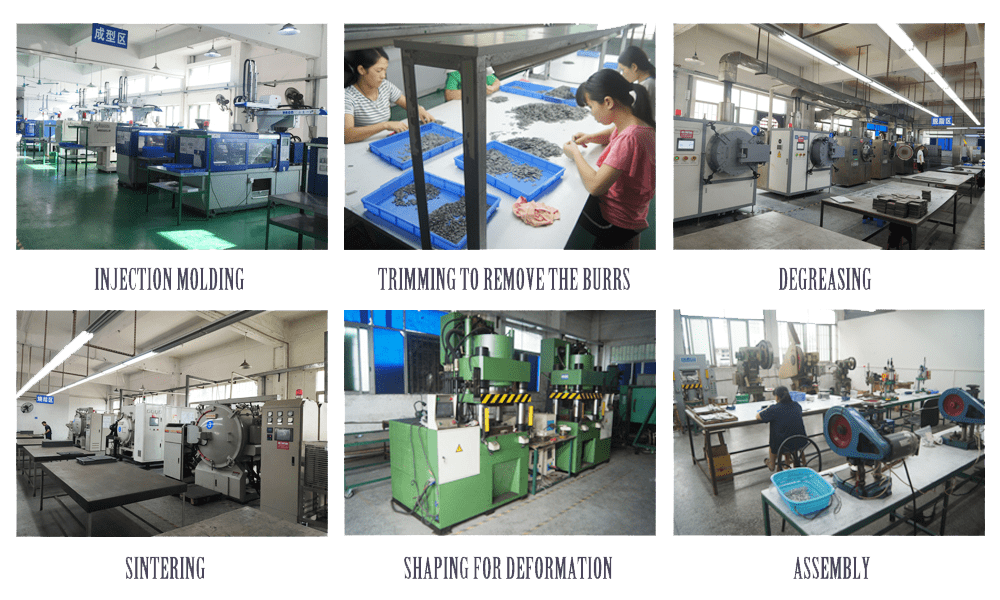

MIM PROCESSES  The CORE TECHNOLOGIES KELU has are MIM and CNC, both for the high-end sport components. Metal injection molding (MIM) is a revolutionary technology which integrating Plastic Injection Molding, Polymer chemistry, Powder metallurgy and Metallic materials science. We can develop mold for special customized size/shape or produce by existing mold directly. Tungsten, Brass, Stainless Steel could be chosen as materials for MIM. Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. And its applicative materials include Titanium, Tungsten, Aluminum, Brass, Stainless Steel, Zinc and so on. KELU’s Main Markets: North American, Europe, Australia, AsiaSpecifications:

The CORE TECHNOLOGIES KELU has are MIM and CNC, both for the high-end sport components. Metal injection molding (MIM) is a revolutionary technology which integrating Plastic Injection Molding, Polymer chemistry, Powder metallurgy and Metallic materials science. We can develop mold for special customized size/shape or produce by existing mold directly. Tungsten, Brass, Stainless Steel could be chosen as materials for MIM. Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. And its applicative materials include Titanium, Tungsten, Aluminum, Brass, Stainless Steel, Zinc and so on. KELU’s Main Markets: North American, Europe, Australia, AsiaSpecifications: | WEIGHT (g) | 45 | 60 | 80 | 100 | 120 | 150 |

Colors: Plain, Shinny Black, Oxiden Matt Black, Green pumpkin, Rainbow, Red, Junebug Material: 97% Tungsten Coat: Plain & Oxide & Painting Tube Choice: With plastic tube or not Unit price (EXW): US$0.1~$2.0 based on weight and quantity Payment Term: T/T, Western Union, Paypal, L/CBUYERS REVIEW

Heavy worm weight,

Miscellaneous,

Divot Tool,

Jewelry Component,

Sinker,

Medical Dressing,

Slotted Tungsten Beads,

Carbide Pellet,

skirted punch weight,

Hunter,

The CORE TECHNOLOGIES KELU has are MIM and CNC, both for the high-end sport components. Metal injection molding (MIM) is a revolutionary technology which integrating Plastic Injection Molding, Polymer chemistry, Powder metallurgy and Metallic materials science. We can develop mold for special customized size/shape or produce by existing mold directly. Tungsten, Brass, Stainless Steel could be chosen as materials for MIM. Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. And its applicative materials include Titanium, Tungsten, Aluminum, Brass, Stainless Steel, Zinc and so on. KELU’s Main Markets: North American, Europe, Australia, AsiaSpecifications:

The CORE TECHNOLOGIES KELU has are MIM and CNC, both for the high-end sport components. Metal injection molding (MIM) is a revolutionary technology which integrating Plastic Injection Molding, Polymer chemistry, Powder metallurgy and Metallic materials science. We can develop mold for special customized size/shape or produce by existing mold directly. Tungsten, Brass, Stainless Steel could be chosen as materials for MIM. Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. And its applicative materials include Titanium, Tungsten, Aluminum, Brass, Stainless Steel, Zinc and so on. KELU’s Main Markets: North American, Europe, Australia, AsiaSpecifications: